Through investing in

technology we have decreased

operational costs by 75%

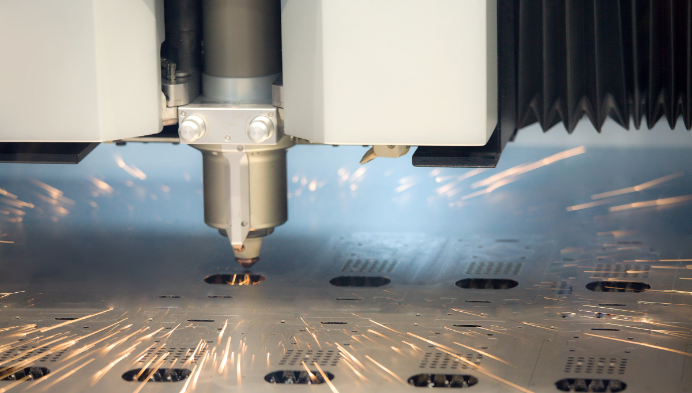

Laser Cutting

R E Cooke is a leading specialist in the laser cutting of sheet steel, stainless steel and aluminium. Our Bystronic CNC laser is capable of cutting the most complex of shapes from these materials. As per our commitment to continual improvement we have invested heavily in our primary process machinery. Since the procurement of a Bystronic laser we have seen dramatic improvements in efficiency in this process.

To ensure the laser operates at the maximum speed possible, without compromising quality of finish, we cut the material in a nitrogen atmosphere. The nitrogen is manufactured on-site and fed directly to the laser. This in-house nitrogen generation ensures that overhead costs are kept under control.

BENEFITS OF LASER CUTTING

Where possible holes and features are laser cut, rather than post drilled or machined. Working from in-house created, or customer supplied, .dxf's or .dwg's ensures accuracy to drawing. Additional features such as surface location marking or etching are also possible to be applied, saving process time downstream. Cross contamination of different materials is avoided by "swap out" of the laser bed slats. Other benefits of laser cutting are: -

- High cut quality and finish

- Clean cut edge finish

- 100% repeatibility

- Automated process

- Ability to cut intricate shapes